Narrow window to clear closed US port hinges when demand plummets

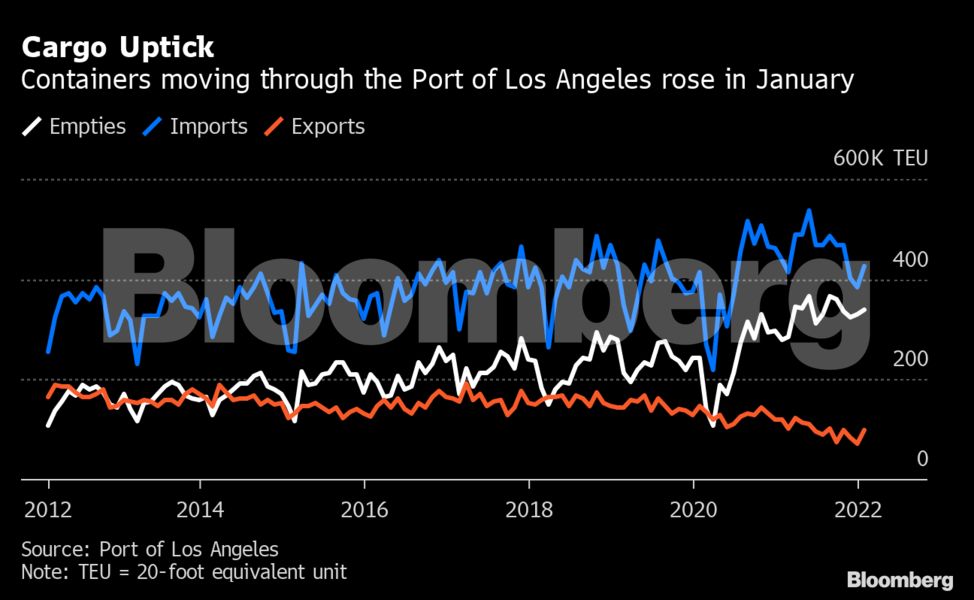

(Bloomberg) — Bottleneck ports in Los Angeles face a narrow window between now and mid-year to clear container backlogs ahead of another import surge and union-contract negotiations as the busiest U.S. gateway for trade. A record volume of cargo through the medium threatens to halt progress.

There are good operational reasons for optimism that LA and Long Beach will provide substantial relief over the next four months. The number of incoming ships has dropped by nearly a third since peaking at 109 in early January, stacks of longer-stay containers are shrinking and ommicron cases are fading among dockworkers.

There is also room for caution in view of the economic tide floating against the ports. Consumers have so far shied away from inflation and continue to spend. Companies are still ordering more and earlier than usual, turning the last 18 months into a long peak season for shipping. Another incentive to stock up: A potentially disruptive contract renewal for West Coast longshoremen.

“This increase in demand is what creates the challenge,” said Julie Gerdmann, CEO of supply-chain risk analytics firm Everstream Analytics. She called it a dance between “just in time” and “just in case” inventory management brought on by the pandemic that has restarted global business.

On the front lines are union workers who load and unload dozens of ships each week in Southern California. Although negotiations are expected to begin as soon as next month, the current six-year contract between the international longshore and warehouse union and their employers, represented by the Pacific Maritime Union, expires on July 1.

This can be controversial and stakeholders at every link in the supply chain are taking notice.

In the final round of contract negotiations that began in 2014, disagreements lasted nine months, leading to a nationwide economic crisis, long lines of waiting ships and shortages of some consumer goods. It took the shipping industry eight to nine months after a deal to return to normal service was struck in February 2015, according to an analysis by Copenhagen-based C-Intelligence.

Now flush with cash, shipping lines are looking to invest in increasing productivity at their terminals — like the software, artificial intelligence and autonomous devices that often replace people. With labor shortages across the country, issues such as automation, wages and benefits may be more contentious than ever for working. Add to this the relatively pro-labor stance of the Biden administration and the record profits of foreign-owned shipping companies, and the leverage could shift to the union.

‘Don’t get caught’

Retailers want to make sure they don’t get caught up in delays again, said Jonathan Gould, the national retail federation’s vice president for supply chain and customs policy. “So they’re going to start bridging and reducing the risk of potential recession disruptions,” he said.

Walmart Inc., reporting a positive outlook for business this year, showed last week that large retailers are better able to navigate scarce transportation capacity, higher wages and rising fuel costs. Meanwhile, Bed Bath & Beyond Inc. said it raised some prices and adjusted its discount strategy due to “broader freight and supply-chain headwinds.”

Read more: US retail sales rise by most in 10 months in broad-based rebound

This year some purchasing managers are already ordering goods before the expiration of the contract, and considering routes through ports on the Gulf Coast or East Coast, or to try for air freight where possible . The ports of Houston and Charleston, South Carolina, have also been overrun with container ships in recent weeks, so options are limited.

Gerdmann said his customers are monitoring choke points and risks that could affect their ability to bring products to market. They are ordering a security or buffer stockpile before the next peak, or are considering moving ports to other regions or other modes simultaneously. “We have customers who are making inventory build-up decisions, even when profitability takes a hit.”

Jean Cerocca, executive director of the Port of LA, sees retailers spend the second quarter restoring inventory to their lowest in a decade. He said last year stores stocked earlier than usual were rewarded with solid holiday sales — a pattern that could happen again this year. “We just have to field and be ready for the peak of that summer,” he said last week at an event announcing LA’s strongest January volume on record.

Seroca’s immediate move is to boost trucking and rail capacity so that containers don’t sit on the side of docks for long periods of time.

Truckstop.com’s chief relations officer, Brent Hutto, said it will take some time to get the work done under the extreme pressure on the various modes of freight. “It’s likely to be the end of this year, early next year for all the cargo to come out of this overflow,” Huto said.

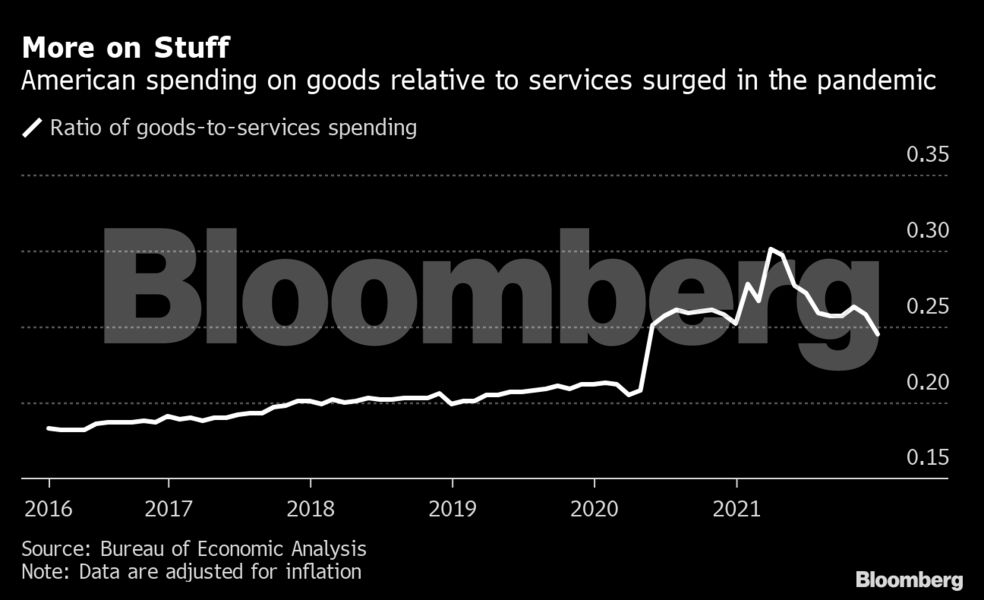

Still, some factors are beyond the control of port operators and have more to do with the wider health of American consumers. Flexport Inc. Chief economist Phil Levy is tracking individual consumption expenditure on goods versus services as a gauge of “normal.”

“For many years before the pandemic, it’s a really flat boring graph and it almost stood still,” Levy said. “And then in the pandemic, it just shot up.”

The latest reading from Flexport’s post-Covid indicator showed that US consumers’ preference for services will continue in the first quarter at a level close to that of summer 2020. And while the PCI showed the proportion of consumer goods, total spending fell to 99% of pre-pandemic levels in December, with the new reading projecting 106% for January.

Such strong demand only complicates the efforts of the ports. A separate Flexport Index showed that cargo was still spending close to a record time – more than 100 days – in transit from Asia to the Americas and Europe.

© 2022 Bloomberg LP